RACEarch Lab

The RACEarch Lab is dedicated to the viscoelastic, dynamic, and thermodynamic characterization of tires, as well as the roughness characterization of the surfaces they interact with. The laboratory is equipped with several key test benches, including a laser for thermodynamic analysis, a hydraulic press for static characterization, and the Vesevo system for viscoelastic characterization of the tire compound. Additionally, it features a rugosimeter to analyze the roughness of road surfaces or test samples, alongside the linear friction tester and the British Pendulum Evolved, used for friction and wear studies.

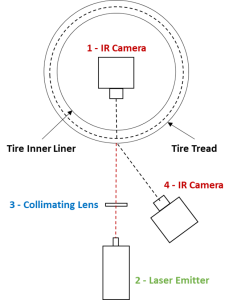

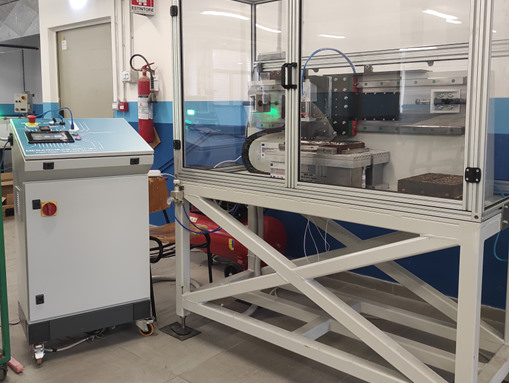

The laser test bench aims to nondestructively characterize the thermal diffusivity of tire layers through a laser beam generator with adjustable power.

The laser beam is focused on a small spot on the tire. One thermal imaging camera acquires the temperature of the heated zone of the tread and another thermal imaging camera measures the temperature on the corresponding area of the tire inner liner.

It is possible to understand how fast the heat flux is evolving inside the tire layers without damaging the tire. Therefore, the tire layers’ thermal diffusivities can be evaluated in a non-destructive manner.

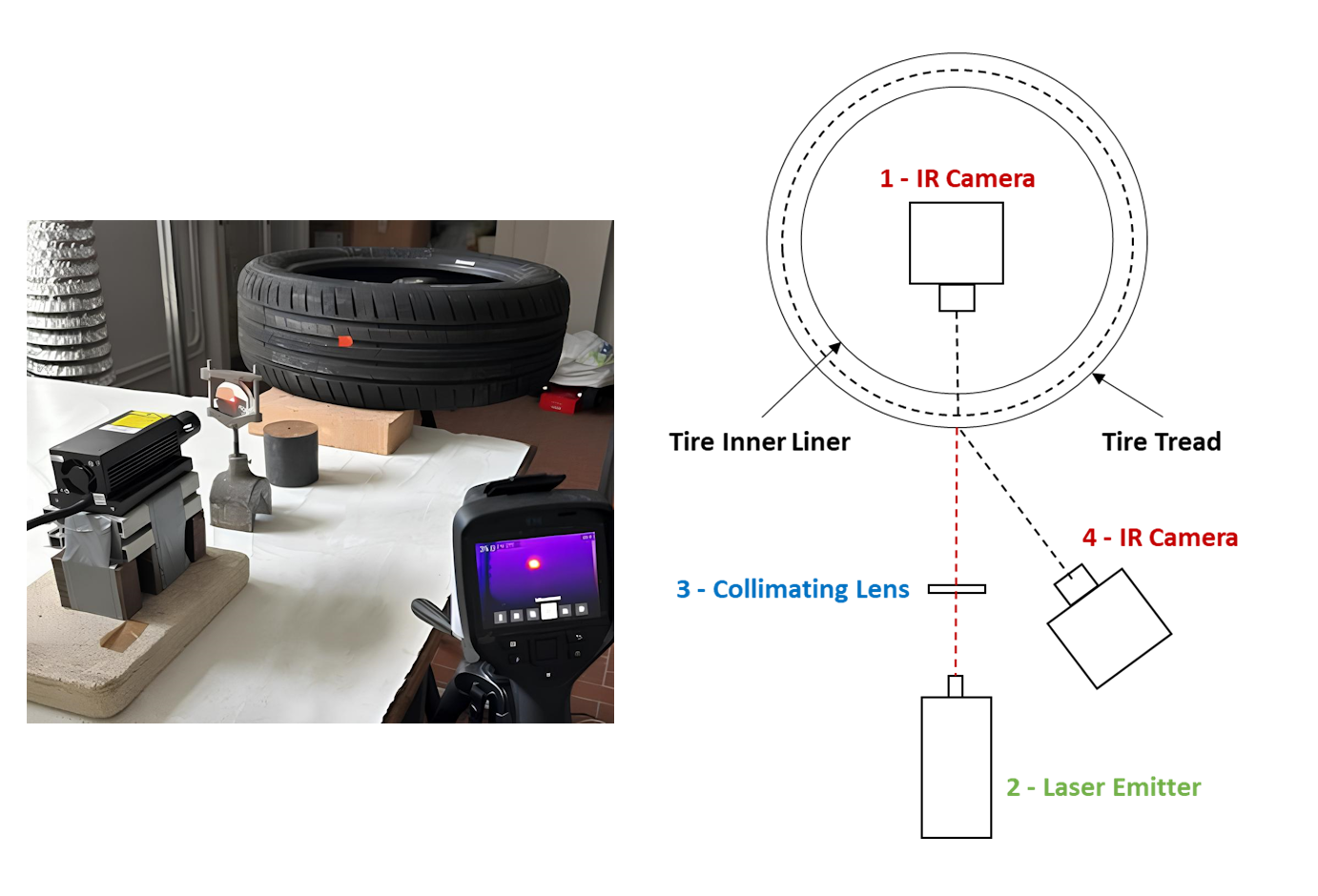

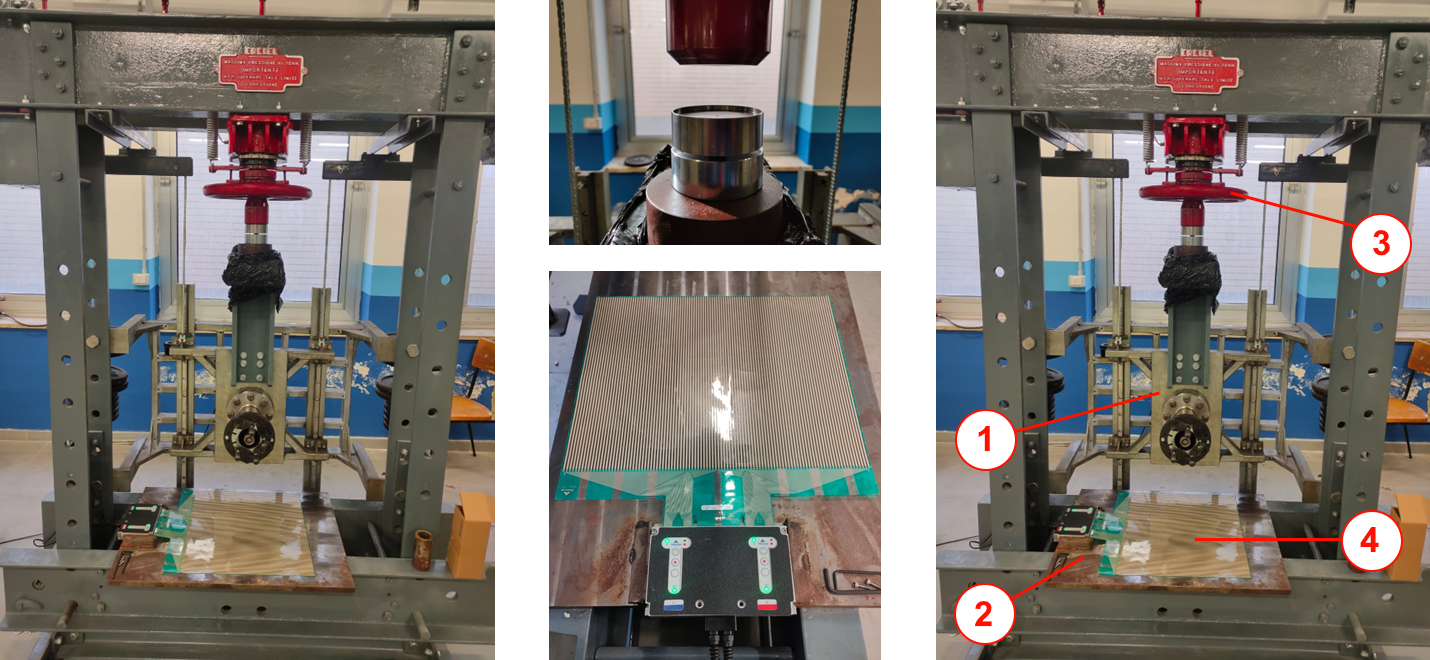

The hydraulic press test bench is designed for static tire testing, allowing control over parameters like vertical load (Fz), inflation pressure (p), and camber angle (γ). Vertical load is regulated by a hydraulic system, while camber angle adjustments can be made by using a dedicated arm on which the tire is mounted. Throughout testing, the vertical load, wheel displacement (distance between wheel center and contact surface), contact patch area, and pressure distribution are recorded.

In particular, the vertical load is measured with a load cell, the wheel displacement with a draw-wire sensor, while the pressure distribution is highlighted using a sensor developed by Tekscan, the “tire footprint pressure mapping system”, which allows both a visual capture of the footprint and the pressure distribution within the contact patch, displayed on a color scale.

The tested tire is mounted on a vertically mobile frame (1) that is lowered until it crashes against a fixed plate (2) with a load imposed by a hydraulic press (3), mounted on a fixed frame. The load cell collects the vertical force during the test, and a draw-wire sensor measures the displacement made at the center of the hub. Eventually, the contact patch can be obtained with the pressure-sensitive sensor (4) placed between the tread and the fixed plate, subsequently analyzed with suited software to obtain the pressure distribution.

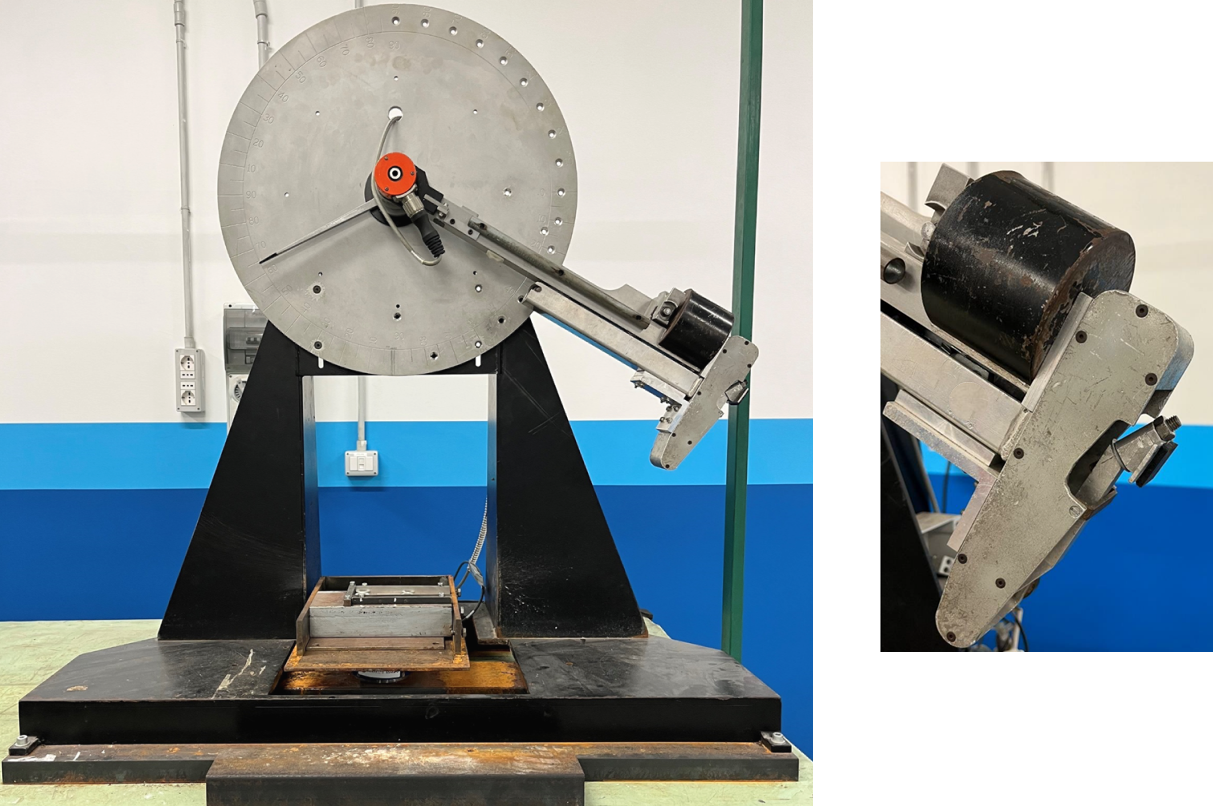

The British Pendulum Evolved (BPEvo) represents an improvement of the classic British Pendulum device. In the British Pendulum, a rubber specimen is mounted at the end of an oscillating arm, which is set in motion to slide the specimen across a substrate, replicating the behavior of a pendulum with a mass at the end. The innovation of the BPEvo is the integration of two additional sensors: a triaxial load cell and an encoder. The first one measures the tangential and normal forces generated during the contact between the rubber specimen and the substrate, while the latter records the velocity of the pendulum arm. This instrumentation allows for the evaluation of the friction coefficient (μ) by analyzing the recorded data mentioned. The oscillating arm also incorporates a spring and a lever system to ensure appropriate contact pressure during sliding.

The substrate or rubber specimen are heated up to the testing temperature with a heat gun. The oscillating arm is brought up to the desired inclination angle, depending on the sliding velocity of the test. The pre-loading spring and vertical position of the graduated crown are chosen to adjust the contact pressure . The test begins when the arm is let fall and the encoder and load cell start to acquire the forces and velocities during the motion which will be later processed.

The Linear Friction Tester is a tool for analyzing the interactions between rubber materials and various surfaces. It allows for a detailed examination of how several factors, such as temperature, road roughness, viscoelastic properties and sliding velocity influence the friction coefficient. By simulating real-world conditions, the test bench allows to understand how these variables impact friction and wear. Additionally, the device is valuable for comparative studies, offering insights into the performance differences between different rubber compounds or surface types. It is particularly useful in assessing the effects of environmental factors, such as wet roads, providing a comprehensive evaluation of rubber friction behavior in diverse conditions.

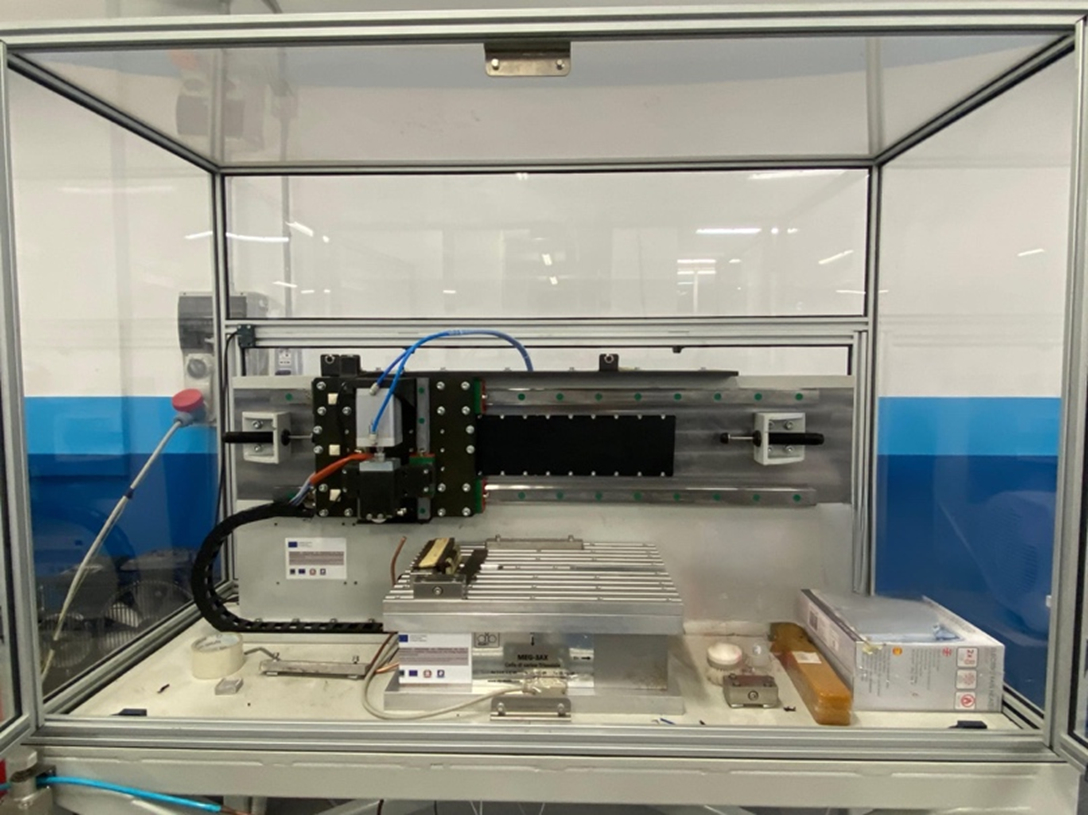

The Linear Friction Tester (LFT) was developed by the Applied Mechanics Research Group of the Department of Industrial Engineering of the University of Naples “Federico II” for friction and wear tests. The test bench aims to reproduce rubber-substrate interactions over a wide range of working conditions. It consists of a table on which a substrate is fixed and on which a rubber specimen can slide.

The main quantities which characterize the different working conditions on the linear friction tester are the tire temperature, contact pressure, sliding velocity, compound specimen and substrate. The rubber specimen sliding motion on the given substrate can be in a single direction for friction measurements or backwards and forwards for a fixed number of cycles for wear measurements. During the motion, the contact forces are measured via a triaxial load cell for subsequent analysis.

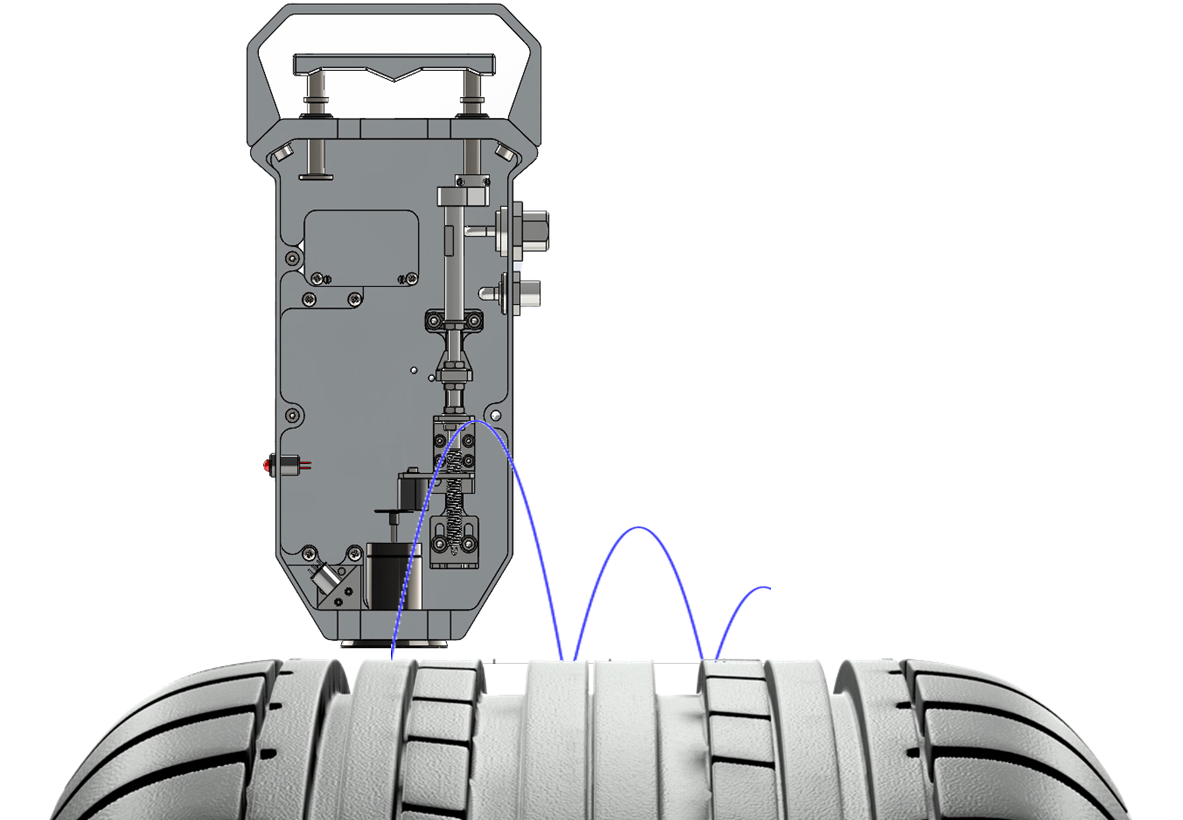

The VESevo, acronym of Viscoelasticity Evaluation System Evolved, was developed by the Applied Mechanics Research Group of the Department of Industrial Engineering of the Naples University Federico II. It allows users to characterize the viscoelastic properties of the tested material, such as a tire tread, in terms of the storage modulus and loss factor master curves and to obtain some characteristic indexes such as the HVI (Hysteretic Viscoelastic Index) and AVI (Adhesion Viscoelastic Index) with a non-destructive procedure.

The device enables the testing of tires tread of any category. A laser sensor measures the bouncing motion of a rod, a semi-spherical indenter, on the material to be tested. The base of the VESevo device must be placed correctly on the surface so that the rod tip hits it orthogonally. A temperature sensor measures the temperature of the tested area, which can be uniformly heated or cooled for testing. The data acquired, i.e. the bouncing curve of the rod, are then processed and allow to obtain the viscoelastic characterization of the tire tread.